Oil is one of the best-needed things for an automobile Engine. It is called the life-blood for any engine. The lubrication system is very similar to our circulatory system. It is considered that the oil is like blood, the oil pump is the heart, and the oil filter is like the equivalent of our lungs and kidneys that clean the oil. So that the lubrication system is crucial for a motorbike. Here we are going to describe how does motorcycle lubrication system works.

Table of Contents

What Is Lubrication System?

A lubrication system is an important and necessary process for an Automobile Engine. Generally, an engine consists of various rotating and moving parts, so we need to lubricate it well; otherwise, they wear and tear out. We sometimes face Engine breakdown problems. The lubrication system can increase this problem. That’s why the use of lubricants is a widely used method.

Motorcycle Engine Lubrication Process

Two metallic surfaces make direct contact with moving over each other; they create friction and produce heat. Reducing the wear and tear of the moving parts provides a cooling effect on the hot engine parts. It also provides a cushioning effect against vibrations that are made by the engine. By carrying out the internal cleaning of the engine, it helps piston circles to seal against high-pressure gases in the cylinder. By supplying a flow of a lubricating substance, the moving parts have been separated. The lubricant may be liquid, gas, or solid. Mainly the liquid lubricant is used in the engine lubrication system.

Types Of Engine Lubrication System

Through various studies, the engine lubrication systems are divided into six ways: the Petrol system, the Splash system, the Pressure system, the Semi-pressure system, Dry sump system, and the wet-sump lubrication system. For the convenience of your understanding, I am going to discuss in detail about these topics. Keep reading to know more.

Petrol Lubrication System

Petrol system lubrication is commonly used in the two-stroke engine such as scooters, motorcycles. Basically, a certain amount of oil is mixed with petrol itself in this type of system. As a result, 3 to 6% of oil mixed with fuel. The portion of this mixer should be proper. If it less, it will be very harmful to the engine. On the other hand, if the mixer portion is more, the engine gives dark smoke and excessive carbon.

Petrol Lubrication System

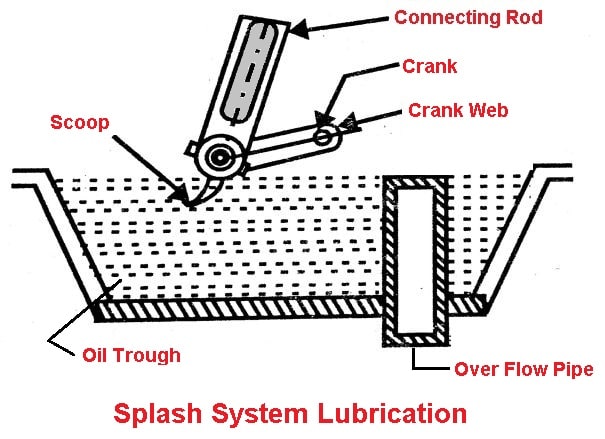

Splash Lubrication system

In presently Splash system lubrication method is the most popular type of lubrication system, and this is one of the cheapest methods of the lubrication system. This system consists of a scoop fitted at the lower end of the connecting rod; when the engine runs, the scoop splashes the oil flow to all engine parts from oil through centrifugal force.

Splash Lubrication system

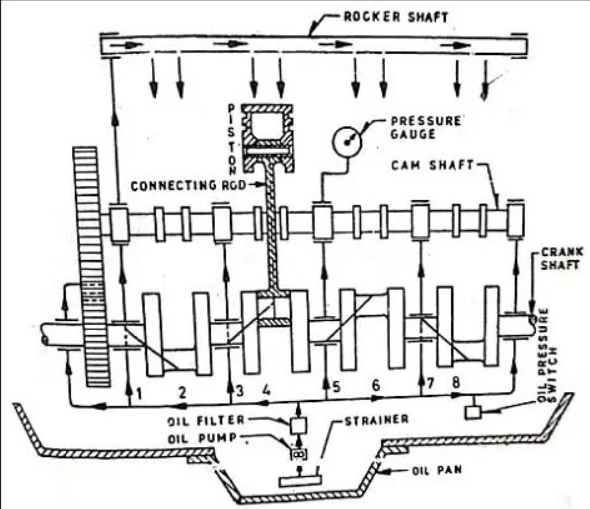

Pressure Lubrication System

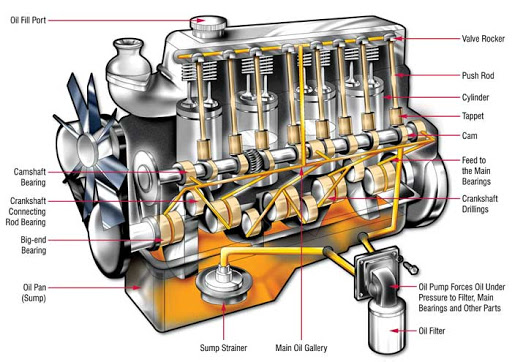

Splash system is for the small engine and not sufficient for larger engines like Ambassador, Jeep, Ashok Leyland, and others; that’s why the Pressure system is used. Oil from the sump is supplied via strainer and filter to the engine parts through main galleries. In this process, the oil pressure is about 2 to 4kg/cm2.

Pressure Lubrication System

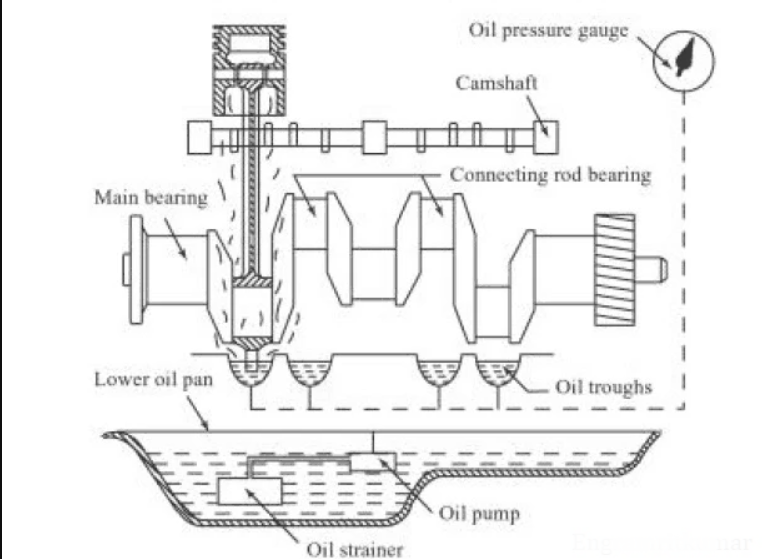

Semi-Pressure Lubrication System

On this lubrication, the pressure of oil is between 0.4 to 1 kg/cm2. In the Semi-Pressure lubrication System, some engine parts are lubricated by the splash system, such as cylinder wall, piston, piston pin, connecting rod, and a pressure system lubricates the remaining parts. That’s why this system is called a semi-pressure system.

Semi-Pressure Lubrication System

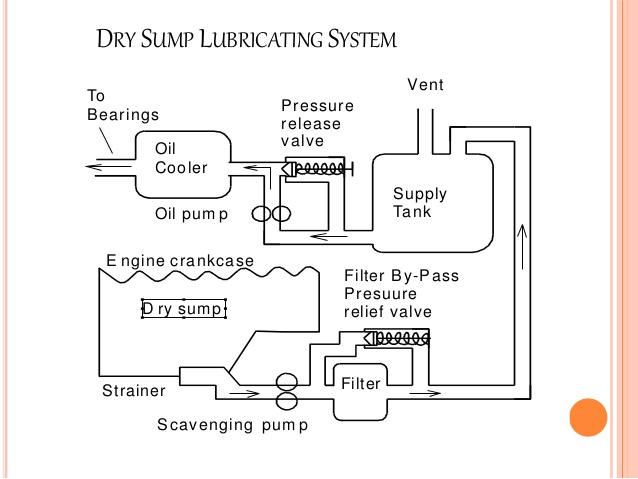

Dry Sump Lubrication System

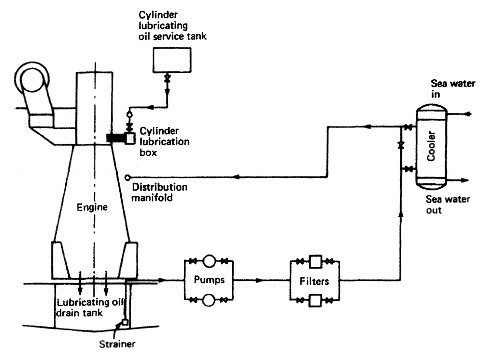

It is a method to conduct the lubricating motor oil in four-stroke and large two-stroke piston-driven internal combustion engines. The Dry Sump lubrication system uses two or more oil pumps and a separate oil reservoir—this lubrication method instead of the current wet sump lubrication system.

Dry Sump Lubrication System

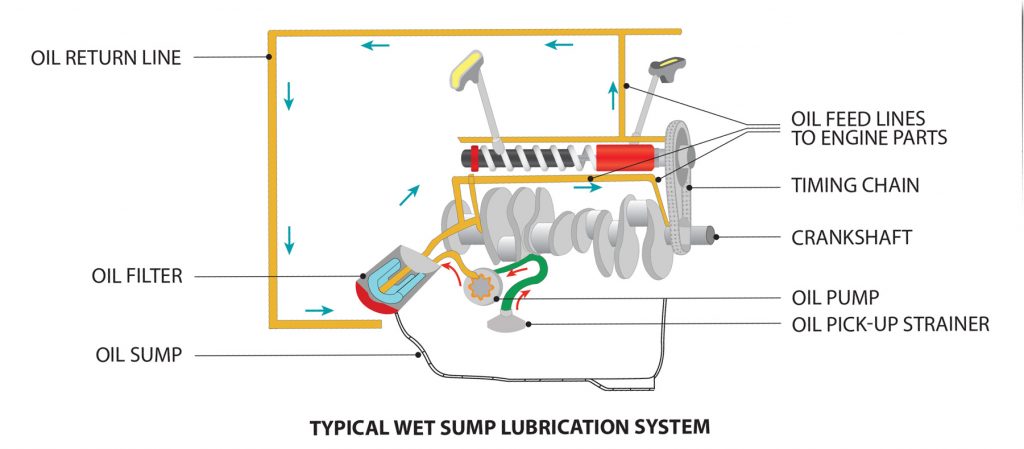

Wet Sump Lubrication System

The wet-sump lubrication system is widely used. The Oil of this system is delivered from the sump strainer to different engine parts. In this process, the pressure of this oil is about 4 to 5kg/cm2. In this system, the oil again back to the oil sump after completing the lubrication. That’s why the oil is always present in the sump. So this system is called a wet sump lubrication system.

Wet Sump Lubrication System

Components of Engine Lubrication System

Oil Sump is a component of an engine lubrication system, a reservoir that looks like a bowl. The engine oil is stored in this oil pan and runs in the engine. The oil pan is located at the bottom of the engine for collecting the engine oil. The bad condition of roads could damage it. The oil pump is also a component of the engine lubrication system, and it helps to run the lubricant oil to all the parts that move inside the engine. At the bottom of the crankcase, the oil pump is located.

Oil galleries are also an essential part of the engine lubrication system for getting better performance and long life of the engine. This is just a series of interconnected passages. It supplies the oil to the remote parts of the engine. The oil cooler is a part that works like a radiator. When the engine oil becomes hot, it cools down the oil. For getting a better engine performance oil cooler is an essential component. Because it maintains the engine oil temperature and keeps it under control. The engine oil filter is also a vital part of filtering engine oil. Here we also point out the components of the engine lubrication system below.

- Oil Stump

- Engine oil filter

- Piston cooling nozzles

- Oil Pump

- The Oil Galleries

- Oil Cooler

- The Oil pressure indicator/light

Actually, What Lubrication Does

The lubrication emerges as an important process of the engine for its own physics. You may know so far that a machine consists of a large multitude of sliding parts. When the engine runs, these parts are moving, and sliding amongst each other creates an incredible amount of friction. The extensive friction generates heat. Like that, the friction of two metallic surfaces makes intense temperature, which temperatures can actually get to the point that the metal parts will begin to mold and fuse together. Even the entire engine will destroy at a point. But the lubrication process can prevent this from happening altogether. This process reduces the friction between the moving metallic pieces. The lubrication process has so many advantages. I am going to show you some. Below some reasons are given of lubrication system importance.

Increase Engine Life

Moving parts of the engine will decay over time at varying rates. The use of quality lubricants is a prevalent method to enable the lowest amount of degradation. The lubricants make sure that all the moving parts of a functioning engine can move without glitches and intense heat. High-quality auto lubricants integrated vehicle can get anywhere from a few thousand miles to as much as 100,000 miles of extra life.

Saves money

Proper engine lubrication will keep an engine alive for longer; I think it will be a generous gift to your wallet. Taking care of your vehicle with high-quality lubricants can be saved more in the long run.

Performance

The quality auto lubricants also allow the vehicle to operate at ultimate efficiency and performance. You can see the performance difference between a lubricated and an unlubricated engine. Proper lubricants can equate to lower fuel costs and more power.

Cooling

lubricating oil carries heat away from the component, which is lubricated. Again the oil is returned to the oil pan. Some of the engines incorporate external oil coolers to assist in oil cooling in the oil pan. An engine needs to keep the oil temperature below. And there is no other option except lubrication to keep the engine cool.

Here we mentioned the lubrication system of a motorbike. All the information is taken from a very trusted website. If we made any mistake, please inform that of your valuable comment on the comment box because a human can make any mistakes. Please stay connected with us for further updates. Thank you for being with us.